The Switch to STATIMs

Why the Switch to STATIMs?

Long before I started working here, I viewed Infinite as a studio that set standards that others tried to emulate. Even back in 2001, when I was still an apprentice, Infinite had a reputation in the piercing industry for being progressive. Now, with my years of experience at some great studios behind me, I have the position of head piercer at Infinite. I’m now one of the people in charge of helping to set these standards.

Throughout Infinite’s history, we have primarily used tabletop autoclaves to process our jewelry and tools. When preparing for a piercing, clients have seen their piercers open their tools from freshly sterilized bags, and see their jewelry removed from sterile packages. Our tabletop autoclaves have been generally used to run bulk cycles, to have enough equipment bagged and pre-prepared for several days, weeks, or even months.

Autoclaves need upkeep, maintenance, and repair for things to keep working smoothly and for longevity of the machine. This year, when it came time for maintenance on our machines, we were greeted with the fact that our autoclaves were all going to need extensive modifications to continue to provide the service from them that we require. This put us in a position of asking if it was maybe time to upgrade and try new things. After lots of research, number crunching, and many conversations and meetings with the rest of the piercing staff, I proposed a big change for the studio. Earlier this year, we made the leap into switching our system from conventional tabletop autoclaves—where everything is sterilized in bulk and then securely stored—to converting completely over to STATIM autoclaves in each room.

What’s the Difference Between a Tabletop Autoclave and STATIM?

Steam autoclaves work by using a combination of heat and pressure to kill bacteria, viruses, and any possible disease-causing organisms present on the tools or jewelry we use during piercing procedures. Tabletop autoclaves generally get up to between 230 and 240 degrees fahrenheit, and between 30 and 35 psi (pounds per square inch) air pressure, and run at this pressure and temperature for 30-40 minutes, with a 20-to-30-minute drying cycle afterward. This is why when clients bring their own jewelry back to be repierced we tell them to expect at least an hour wait. We need this time for the autoclave to heat up, reach pressure, depressurize, and dry packaged jewelry.

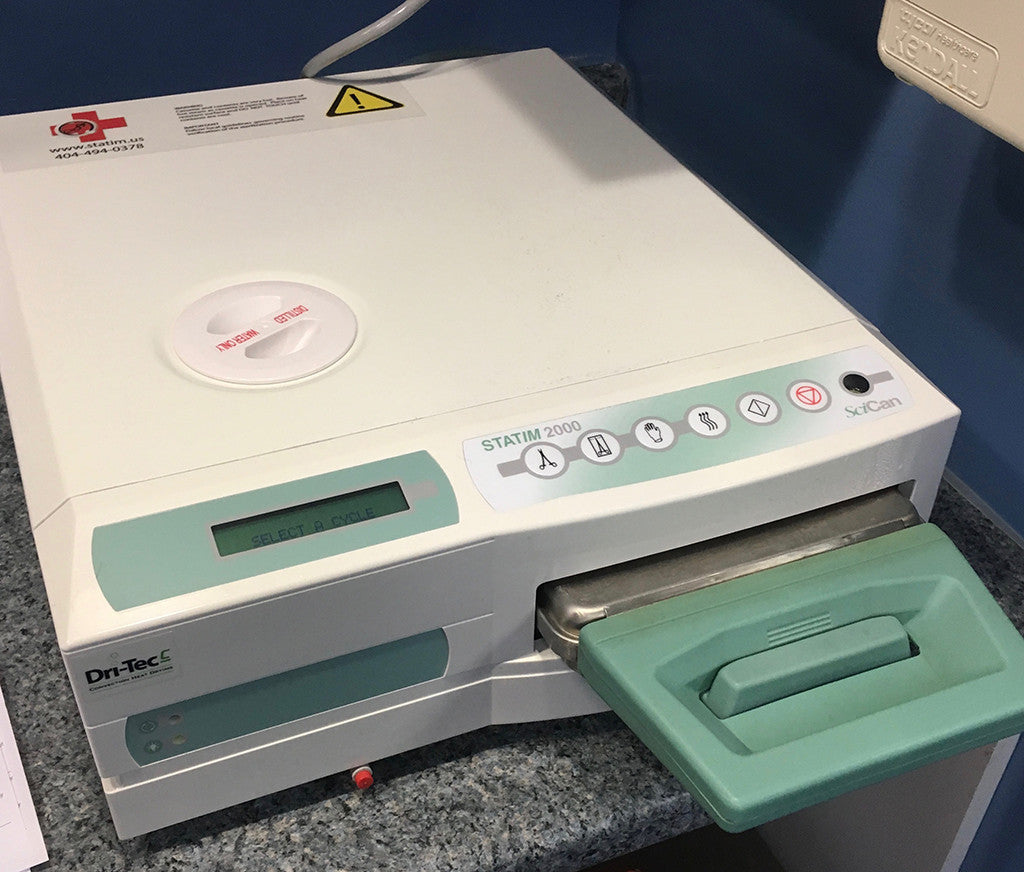

STATIM autoclaves work on the same theory of steam and pressure, however instead of a large chamber that fits multiple pouches you sterilize a small cassette. Along with steam and pressure, a STATIM flushes the chamber with positive pressure pulses. This helps get air out of the cassette faster and allows for pressure and heat to build faster. This, combined with the fact that we no longer have to package tools and other implements in pouches, allows for a much faster and more effective sterilization. With a STATIM, a standard sterilization cycle happens in about six minutes, rather than the forty five minutes to an hour that it takes to sterilize in a traditional tabletop autoclave.

What Does This Mean for our Clients?

Most importantly, what this means for our clients is that we are giving you the freshest and fastest sterilization available.

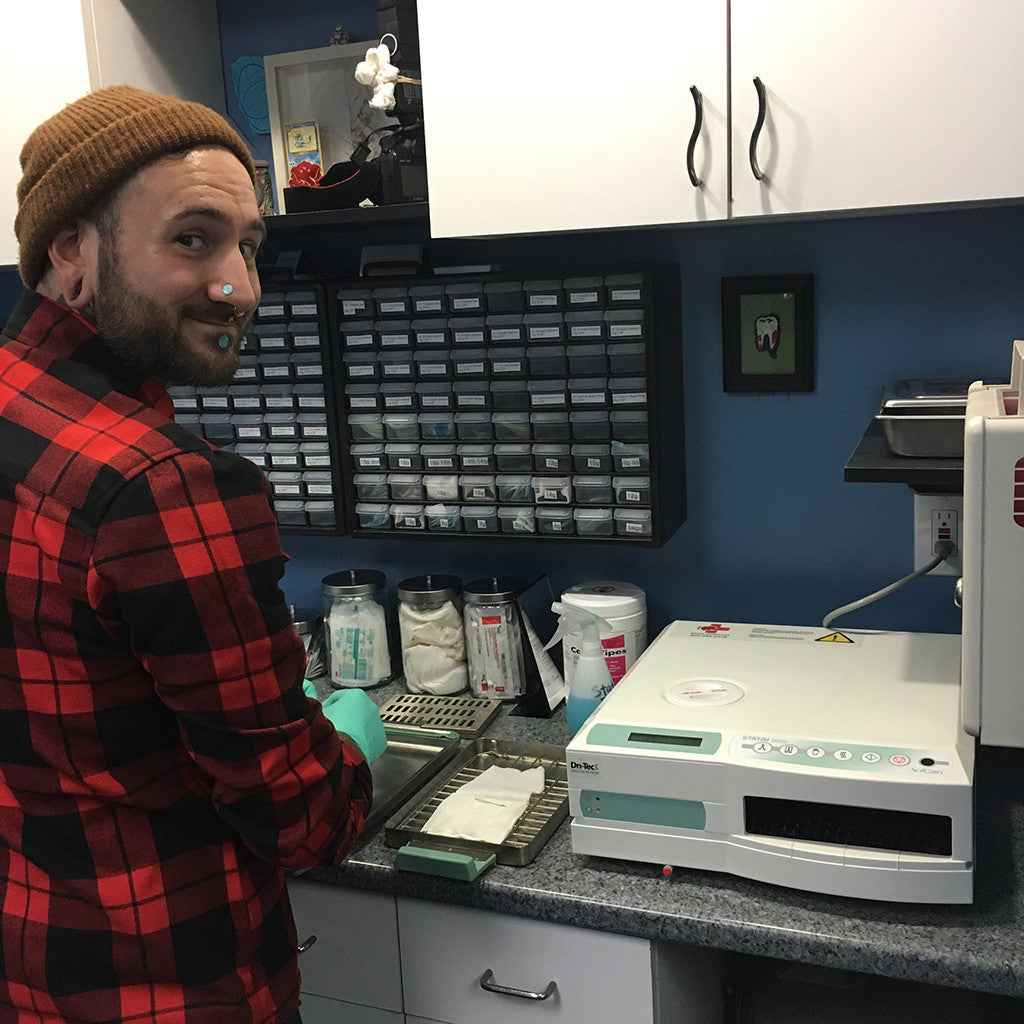

Our customers still select their jewelry at the front counter like normal, but no longer will little pouches be pulled and put on top of your paperwork. With the new STATIM set up, all initial piercing jewelry has been moved into the piercing rooms. You will not be seeing us use jewelry, and or any piercing tools and implements that are being pulled out of drawers and pouches. You will see your jewelry, and the tools being used for your procedure, being removed from the sterilized STATIM cassette in from of you, moments prior to you being pierced. At Infinite, sterilization is now personalized!

We’re using the most thorough, up-to-date, and fastest sterilization equipment available. Even if you don’t care how we sterilize our tools, you can be assured that we’re working to make sure anything that is used for your piercing procedure, either tools or jewelry, is sterile. We’ve put a lot of work into upgrading our equipment, techniques, and workflow, so forgive us if we want to brag a little bit about it.

Editor’s Note: Ed has the gratitude of the entire staff here at Infinite for undertaking and overseeing such a project as large as this one. It makes it even harder to announce that December 31, 2016 will be Ed’s last day at Infinite. – James

Leave a comment